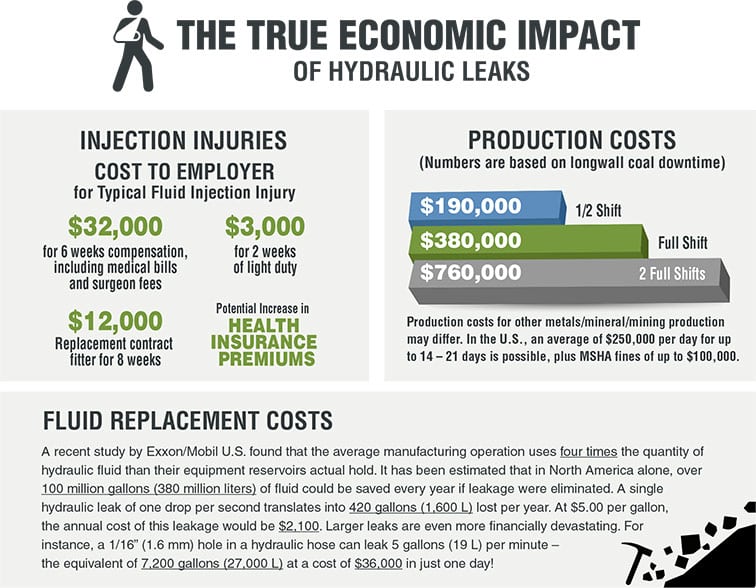

High-pressure fluid injection is a major medical emergency on the worksite. When a confirmed case of accidental fluid injection occurs, all work operations must stop to remove the injured worker and investigate the incident ― costing upwards of $50,000 per hour in lost labor and production!

Studies have shown that the quick and accurate detection and treatment of a fluid injection injury by trained first aid personnel can greatly reduce the injured worker’s pain and suffering, disfigurement and recovery time, as well as improve worksite safety.

In one case study, there were 16 instances at three mining sites where, with the use of FluidSafe additive, paramedics were able to determine that ?uid splashed on mine workers did not actually penetrate the skin. In all instances, the miners were able to quickly return to work and production losses were minimized.

In January 2012, at a mine in Australia that uses FluidSafe, a worker suffered a penetrating injection injury. With the aid of FluidSafe and an associated blue light inspection kit, surgeons were able to clearly see the boundaries of the penetration within the subcutaneous tissue and minimize damaged tissue removal. The lessened pain and disfigurement allowed the worker to return to the job sooner.

Peabody Energy Australia reported a dramatic decline in the number of hydraulic fluid release incidents following the introduction of FluidSafe in all of their fluid power systems in late 2010. In the three years prior to FluidSafe’s implementation, Peabody suffered 155 fluid release incidents. After implementation, they had only 39 incidents in a similar period. In each of those incidents, the use of blue light inspection kits allowed the quick determination of fluid penetration. Only one incident in 2012 turned out to require surgery, and the costs of unnecessary surgical procedures were avoided.

Injuries

High-pressure fluid injection is a major medical emergency on the worksite. When a confirmed case of accidental fluid injection occurs, all work operations must stop to remove the injured worker and investigate the incident ― costing upwards of $50,000 per hour in lost labor and production!

Studies have shown that the quick and accurate detection and treatment of a fluid injection injury by trained first aid personnel can greatly reduce the injured worker’s pain and suffering, disfigurement and recovery time, as well as improve worksite safety.

In one case study, there were 16 instances at three mining sites where, with the use of FluidSafe additive, paramedics were able to determine that ?uid splashed on mine workers did not actually penetrate the skin. In all instances, the miners were able to quickly return to work and production losses were minimized.

In January 2012, at a mine in Australia that uses FluidSafe, a worker suffered a penetrating injection injury. With the aid of FluidSafe and an associated blue light inspection kit, surgeons were able to clearly see the boundaries of the penetration within the subcutaneous tissue and minimize damaged tissue removal. The lessened pain and disfigurement allowed the worker to return to the job sooner.

Peabody Energy Australia reported a dramatic decline in the number of hydraulic fluid release incidents following the introduction of FluidSafe in all of their fluid power systems in late 2010. In the three years prior to FluidSafe’s implementation, Peabody suffered 155 fluid release incidents. After implementation, they had only 39 incidents in a similar period. In each of those incidents, the use of blue light inspection kits allowed the quick determination of fluid penetration. Only one incident in 2012 turned out to require surgery, and the costs of unnecessary surgical procedures were avoided.

Resources

Fluid power safety and hydraulic injection injuries are often underweighted within safety management systems. The resources (links) below draw from a variety of sources to help you better understand the consequences of injection injuries and to provide information about effective fluid power safety systems from world leaders.